SuperPro

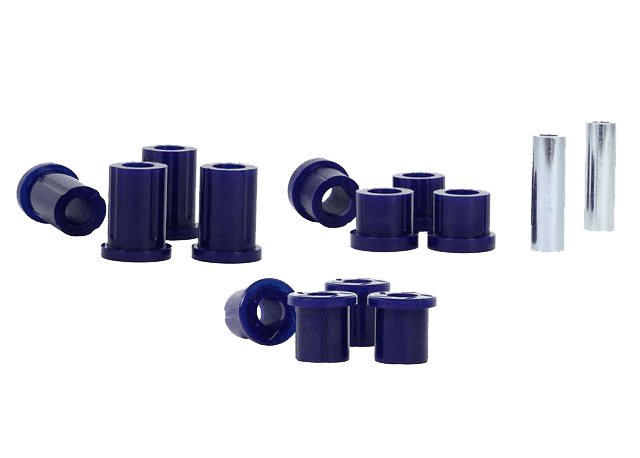

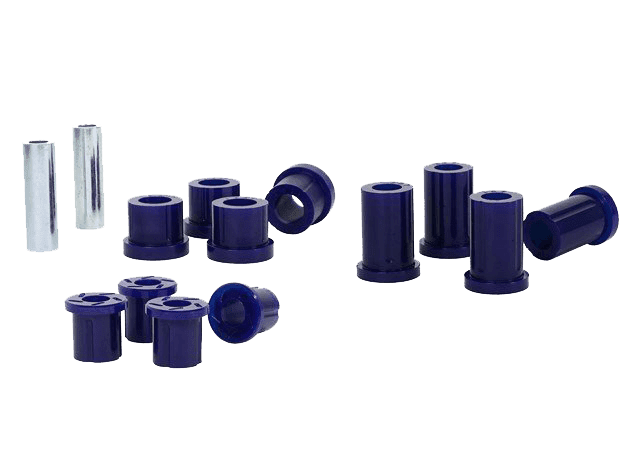

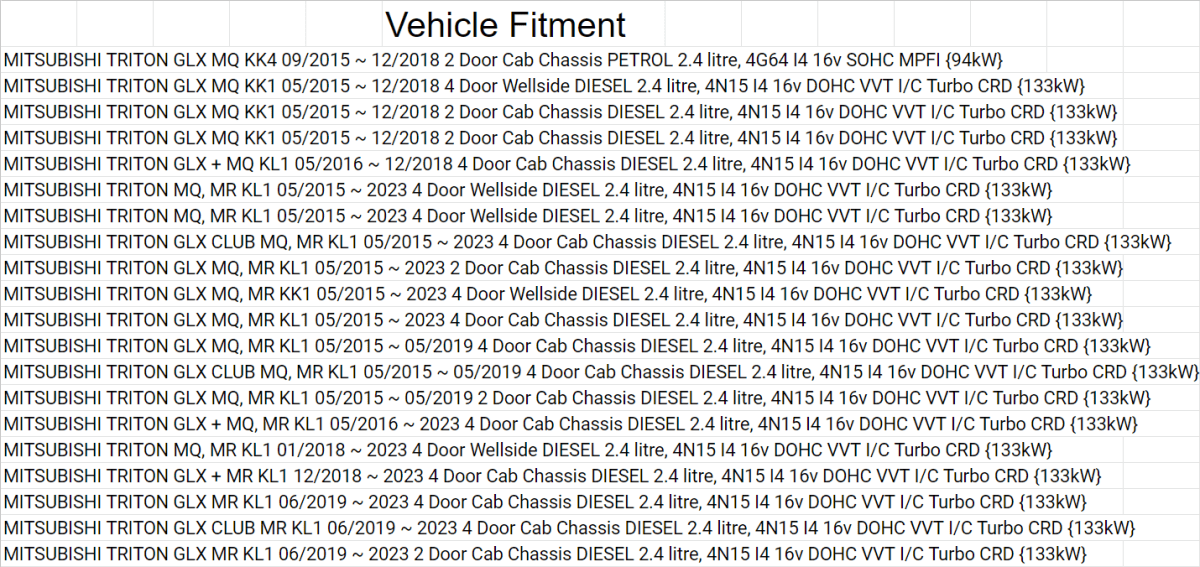

Super Pro Leaf Spring Bush Kit to suit Mitsubishi Triton / L200 / Strada

Super Pro Leaf Spring Bush Kit to suit Mitsubishi Triton / L200 / Strada

SKU:A5-KIT218K

Couldn't load pickup availability

SuperPro Suspension Bushing Features

Some in-built bushing features of our SuperPro Bushes include tangential grooves, knurling, double helix grooves and bullet grooves. These features have been included in the bushing designs for grease retention and to ensure the bushings perform at the highest standard while minimizing excess NVH.

Bullet grooves allow for variances to occur in control arms or spring eyes, although polyurethane is solid when manufactured, the features of the SuperPro bushings, particularly bullet grooves, allow for the bushing to act like a liquid when loaded. This allows the bushing to prevent excessive NVH

Knurling has several design advantages which include grease retention and a reduction in the surface area of the bushing meeting the crush tube. This results in less friction between the two components and allows unrestricted pivoting of the bushing around the crush tube and other steel surfaces.

Tangential grooves are the grease grooves in the head of the shackle bushes. This design results in reduced friction between the shackle bush head and the steel it meets, such as the shackle plates. Another advantage of the tangential grooves is it ultimately reduces noise, as the stored grease is wedged between the two surfaces that meet when the spring shackles rotate.

Double-Helix grooves are used inside the bushing and on the outside surface of the crush tube. This feature allows the grease applied to travel from the center of the bush and out into the grease grooves at the head of the bush, forming a long layer of grease.

SuperPro also uses zinc coated steel in their bushes when required to prevent rusting and ensure the longevity of the SuperPro bushing. Crush tubes are an important part of the SuperPro bushing system and are designed to make sure they are correctly fitted. In most bushings, SuperPro uses a high stress, corrosion resistant and hardnosed Supaloy material. This alloy solution is leaner and lighter, which helps lower the vehicle weight, improve fuel consumption and running costs.

Why SuperPros bushing material is the best!

One of the many benefits of using aftermarket components is that each product is built from scratch. This guarantees the product will exceed standards as a standalone component, rather than as a subordinate component of a larger module as seen in OE engineering. SuperPro embraces the concept of developing a higher quality, noise reduced, longer lasting alternative to standard rubber bushings.

SuperPro bushings are engineered with a proprietary polyurethane. Polyurethane is a special elastomer-based material which gives an extremely durable suspension product featuring the best characteristics of both rubber and plastic. With extensive application products ranging from hard plastics to carpet underlay, SuperPro have developed a unique polyurethane formulation exclusively for use as suspension bushing material. This has resulted in superior mechanical properties to rubber including:

- Superior abrasion resistance

- Excellent memory properties

- Unaffected by extreme temperature, oils and coolant

- Superior control of noise, vibration and harshness (NVH) equal or exceeded OE.

- Not constrained by OE design constraints (mass-production costs, warranty and vehicle assembly factors)

Vertical Pivoting Bushings

The vertical pivoting bush (VPB) is a perfect example in expressing the contrasting performance between OE rubber and poly bushings. This style of bushing was introduced by manufacturers to increase factory efficiency and reduce costs in the assembly of the under carriage and engine modules. The tradeoff is an unfortunate tendency for distortion under high lateral loads and excessive lateral movement of the control arm. Although these original rubber VPB mounts provide a cost-effective mounting solution, in most applications they result in a short service life.

In response to this latent issue, SuperPro polyurethane VPB bush designs ensure that the control arm is positively located in all situations with increased freedom to articulate as intended. This results in a vehicle that brakes safely and predictably, maintaining wheel alignment under all conditions and maximizing your tyre life.

Lifetime Warranty

All SuperPro products are engineered in Australia and are Built to last. This is backed by the lifetime warranty offered by SuperPro for all their bushings.

All SuperPro Suspension Bushings, Sway Bars and Suspension Arms are covered by a Lifetime Warranty. This means that if a SuperPro Product fails, it will be replaced free of charge without exception. SuperPro will also replace any brand of automotive Polyurethane Bushing, which has failed due to factory defects in material and/or workmanship as determined by SuperPro with our own product for free.

⚠️ Important Information: You are responsible for LVV compliance of purchased products and their installation, if applicable. Images are for illustration only, actual product may vary. Please contact us with any questions.

View full details